Technology Nanomembrane

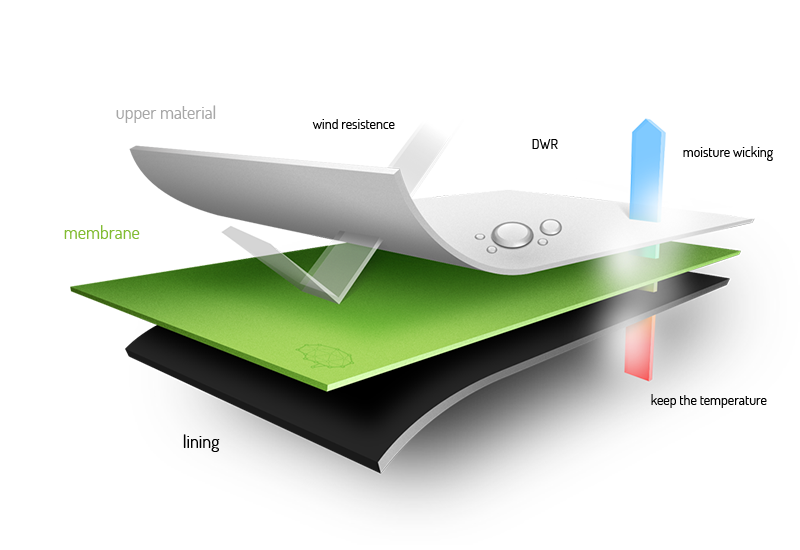

NANOMEMBRANE offers various types of membrane that, in combination with the unique lamination technology, give the laminated products unique properties.

Nano-fabric membrane

It is fully made of PU and the diameter of nano-fibres is just 150 nm. Thanks to this unique structure, the number of pores in the nano-fibre membrane is higher by 25 % compared to other porous membranes (PTFE - GoreTex). Therefore, NANOMEMBRANE can offer laminates with a nano-fibres membrane showing the best vapour permeability world-wide. These laminates are primarily suitable for physically demanding activities such as jogging, biking, hiking etc. Nano-fibre laminates featuring this membrane are offered only in the option 3L.

Micro-porous membrane

The PTFE micro-porous membrane was specially developed for windproof (softshell) and shoe maker´s laminates. Developing it, we placed enormous emphasis first of all on vapour permeability and 100 % resistance to wind. Compared to classic porous membranes, the micro-porous membrane manufactured by NANOMEMBRANE consists of several very thin layers that provide it with exceptional properties for the already mentioned windproof and shoe making laminates.

Non-porous membrane

The non-porous or hydrophilic membrane is made of very flexible PU. Moreover, unlike other non-porous membranes, it excels thanks to low basis weight. Thanks to this, we have achieved a high level of vapour permeability considered by NANOMEMBRANE to be the most important comfort criterion. Moreover, this membrane is typical of high level of wash resistance. This kind of membrane may be used in particular in working clothes or hardshell laminates.

Technology Nanomembrane

Thanks to a unique nanofibrous structure with the fibre diameter of less than 150 nm, on 1 cm2 the NANOMEMBRANE nanofibrous membrane has 25% more pores than microporous membranes. This helps the NANOMEMBRANE achieve unique attributes that no other membranes in the world can match. It is no secret that the NANOMEMBRANE nanofibrous membrane is very similar to human skin, thanks to which NANOMEMBRANE can boast extremely high vapour permeability, i.e. the ability to remove bodily moisture from human skin to the external environment. Vapor permeability of the two layer laminate with nanofibrous membrane is from Ret 0,89. Moreover, the NANOMEMBRANE nanofibrous membrane is 100% wind resistant and it boasts extreme hydrostatic resistance.

Unlike other manufacturers, our company offers not only a choice of our own collection of woven and knitted fabrics, from which we can create a laminate according to your requirements, but we can also laminate on your materials. These materials, however, have to undergo a series of tests. If the material passes all the tests, we can laminate our unique Nanomembrane onto it.

Comparison of the vapor permeability membranes

Hydrophilic

Nanomembrane (nanofibrous)

Microporous

Vapor permeability two layer laminates: from Ret 0,89/130 000 g/m2/24 h THE BEST VAPOR PERMEABILITY IN THE WORLD

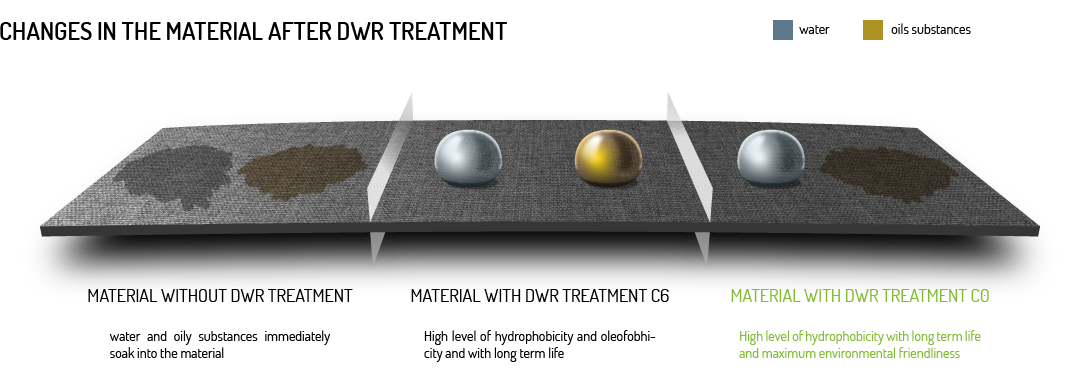

Hydrophobic and oleophobic treatment of textiles - DWR

Moreover, all laminates have a hydrophobic finish using so called DWR treatment. NANOMEMBRANE offers two types of finish: Fluorocarbon type C6 and Fluorocarbon free so called hydrocarbon – PFC-free. Both finish types offer high level of hydrophobicity with similar extremely long service life. The fluorocarbon type C6 has an oleophobic finish a the PFC-free offer maximum possible level of environment protection.