Fashion

The Fashion line as opposed to the Sport and Outdoor lines includes mostly natural materials (cotton, wool). This line is intended for people who want to wear elegant clothes, but want their clothes to meet the strictest criteria in terms of comfort. Materials from the fashion series are offered in the option two-layer and three-layer. All laminates have a hydrophobic finish using so called DWR treatment.

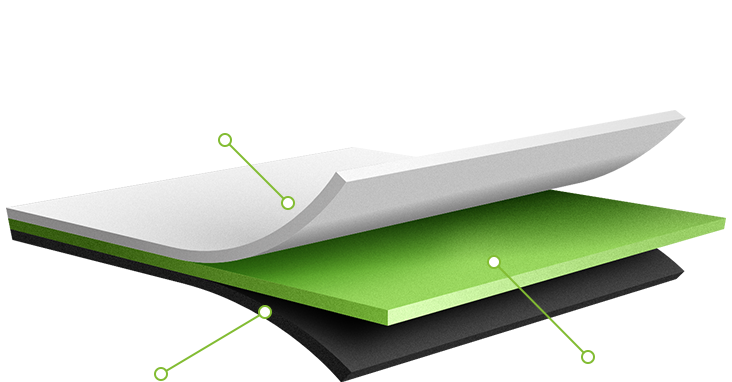

Two layer laminates - cotton, wool

Two layer laminates are offered with hydrophilic membrane and providing excellent weather resistance - wind, rain, snow. The materials retains a sufficiently high water column and a 100% wind resistance. These laminates are intended primarily for winter clothes with an insulated layer or loose lining for summer clothes.

upper material

membrane

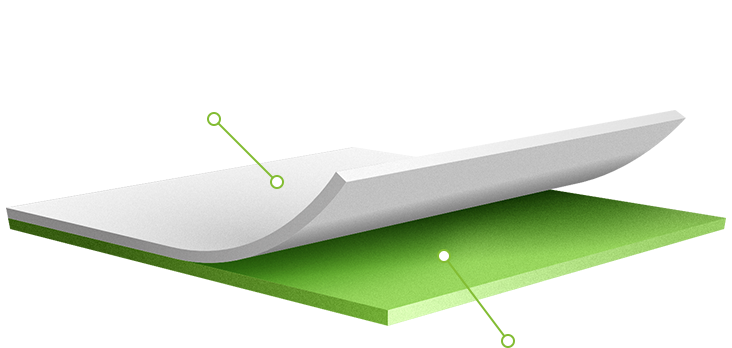

Three layer laminates - cotton, wool

Three layer laminates are offered in the option with nanofibrous membrane or hydrophilic membrane depending on which parameter the customer prefers – high vapor permeability or high water column. These products are primarily intended for spring, summer, autumn and provide also 100% wind resistence.

upper material

lining

membrane